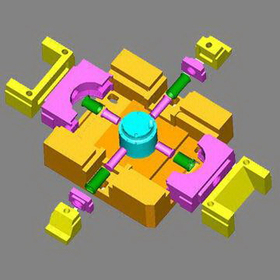

Precision plastic mold design and manufacturing

We can design more precise molds using 3D technology and provide resin flow analysis reports!

We maintain the high quality that Taiwan's manufacturing industry has excelled in, and we provide the best mold manufacturing services. To meet our customers' needs, we offer consistent services such as: → Custom design → Prototypes → Mold production → Production management or reverse engineering → Customer molding and assembly ...and more. Our major clients are spread across the globe, and we receive numerous requests each year from customers in Finland, Sweden, Denmark, the Netherlands, Germany, England, the United States, Canada, South Africa, Syria, Cyprus, the Philippines, and more. We are utilized for prototyping, small lot production, and pilot mass production. For more details, please download our catalog or contact us.

- Company:インターテック マシナリー有限公司(Intertech Machinery Inc.) 台湾本社

- Price:Other

![[Achievements Introduction] Housing Equipment Related](https://image.mono.ipros.com/public/product/image/c6e/2000760051/IPROS15874288123461407096.png?w=280&h=280)

![[Solution Case] If you have a product model, leave the conceptual design of the mold to us.](https://image.mono.ipros.com/public/product/image/6f5/2000879331/IPROS9831767386246923308.png?w=280&h=280)

![[Case Study on Mold Life Improvement] Explanation of the Causes of Mold "Cracking" and Improvement Methods](https://image.mono.ipros.com/public/product/image/cb0/2001016098/IPROS16874417668599354468.png?w=280&h=280)

![[Case Study] Kobayashi Manufacturing Co., Ltd.](https://image.mono.ipros.com/public/product/image/869/2000361957/IPROS4276185379211513833.jpg?w=280&h=280)

![[Case Study] Reducing Waste in Production](https://image.mono.ipros.com/public/product/image/f63/2001538388/IPROS4406928143455314715.png?w=280&h=280)

![Pro Manual! Zero Defect Outflow Countermeasures Quality Improvement Techniques [Complete 8 Series]](https://image.mono.ipros.com/public/product/image/813/2000765622/IPROS35340332026041000038.jpeg?w=280&h=280)